COMPANY PROFILE

COMPANY PROFILE

Fuzhou Rongqing Rubber Co., Ltd. is a Sino-Japan joint venture incorporated by J&C in China in June 1995. Our company, located in Fuzhou, Fujian, boasts easy access to transportation and concentrates a large number of professionals and talents. Our two factories cover a total floor space of 20,000 square meters, bringing about a greening rate of 30%.

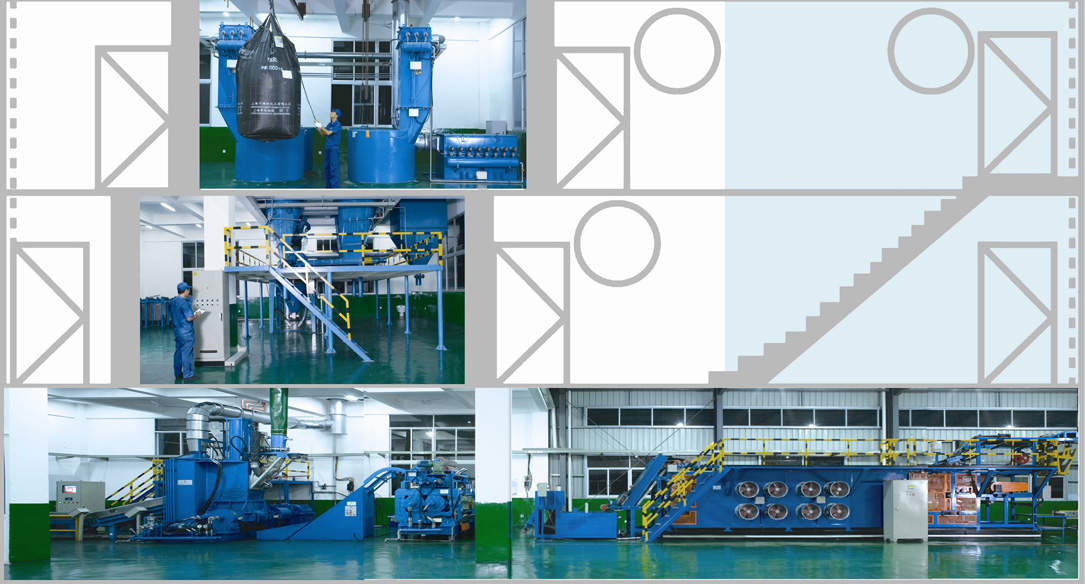

Our company is equipped with a full-automatic material weighing system, an internal mixer auxiliary system, a bar code management system, a forming machine overtemperature alarm system, modern rubber mixing equipment, preforming processing equipment, vulcanizing equipment of various tonnages, as well as complete devices and equipment for experiment, test and inspection. Guided by the development concept of “good faith, harmony, quality and progress”, our company integrates material development, material processing, process design, quality guarantee, and after-sales service and engages in the production of auto rubber accessories and various industrial rubber. Now we have introduced the management concept of Japanese enterprises and obtained a series of management system certifications, including ISO9001:2015、IATF16949:2016、ISO14001:2015 and so on. Besides, we strive to spread the quality concept throughout the company by means of morning conference, work on the spot, weekly meeting, quality meeting and other management methods. By applying the ERP management system, we have been effectively monitoring the production process and product quality and tracing the production files, with the aim of preventing the production and delivery of nonconforming products and making the clients rest assured in both purchase and use of our products. Through concerted effort of all our personnel, we have won continuous and general approval from clients. So far we have rated as “inspection-free enterprise” by many clients, “annual excellent supplier” and other titles. Besides, we have won numerous honors from government of all levels, such as “enterprise that abides by contract and keeps faith”, “enterprise with Grade A tax-paying credit”, “May Day female model of the State”, and “harmonious enterprise”.

Now we offer a complete range of products and are capable of carrying out research and development as per customer requirements. Moreover, we have established favorable partnership with our suppliers and clients, which leads to products in competitive prices and with guaranteed quality. While enjoying a ready sale in domestic and Japanese market, we have been vigorously exporting our products to Europe, America, Southeast Asia, etc.

You are welcome to visit us for cooperation and communication.

DEVELOPMENT HISTORY

DEVELOPMENT HISTORY

-

2021

-

2016

-

2015

-

2014

-

2011

-

2010

-

2008

-

2007

-

2006

-

2002

-

2001

-

1996

-

1995

In January 2021,Import automatic appearance inspection equipment;

In January 2016, we were rated as “supplier with Grade A quality in 2015” by Sanjing Metal Aikete Company (China);

In March 2016, we obtained the ISO14001:2004 environment management system certification;

In March 2015, Quality Inspection Section, Class 2 was awarded the national May Day female model for which Fujian TV station made a special report;

In September 2014, two standard workshops were built in the second factory, and the full-automatic horizontal injection molding machine and colored glue production equipment were also introduced;

In May 2011, we were approved by Honda Motor (Honda Motor Company Limited);

In December 2011, we were awarded the “excellent quality award of 2011” and “free-inspection enterprise” by Shanghai Male Clarification System Co., Ltd. ;

In December 2010, we were rated as “supplier with Grade A quality” by Sanjing Metal Aikete Company (China);

In October 2008, our second factory introduced the computer formula mistake proofing device and full-automatic rubber mixing production line;

In August 2007, obtained the ISO/TS16949:2002 international quality management system certification;

In August 2006, the second factory covering 13,000 square meters was built;

In December 20002, obtained the ISO9001:2000 international quality management system certification;

In January 2001, relocated in new plant of 7,000 square meters;

In June 1996,volume production was carried out;

In June 1995, our company was established;